Kubpak Saddle Rings | Intalox Saddles (IMTP)

METAL - KUBPAK SADDLE RINGS | Intalox Saddles (IMTP)

Metal Intalox Saddles (IMTP) rings are a type of random packing suitable for high capacity & performance applications.It provides low pressure drop which in turn reduces foaming and energy consumption. We have a wide range of metal saddle ring packing options in various sizes and configurations.

- Acid gas removal

- High-pressure distillation

- Sour water stripping

|

|

| Size | 15 to 70 mm |

| Bulk Density | 90 – 350 Kg/m3 |

| Surface Area | 60-285 m2/m3 |

| NTSM | 2.2 to 2.5 |

| Thickness | 0.3 to 0.6 mm |

PLASTIC - KUBPAK SADDLE RINGS

Applications:

- Absorption, extraction and heat transfer

- Production of sulphuric acid

- Dying , scrubbing and stripping towers

|

|

| Size | 25 to 75 mm |

| Bulk Density | 48 – 83 Kg/m3 |

| Surface Area | 89-210 m2/m3 |

| NTSM | 2 to 2.5 |

| MOC | PP, PVDF, PTFE & PFA |

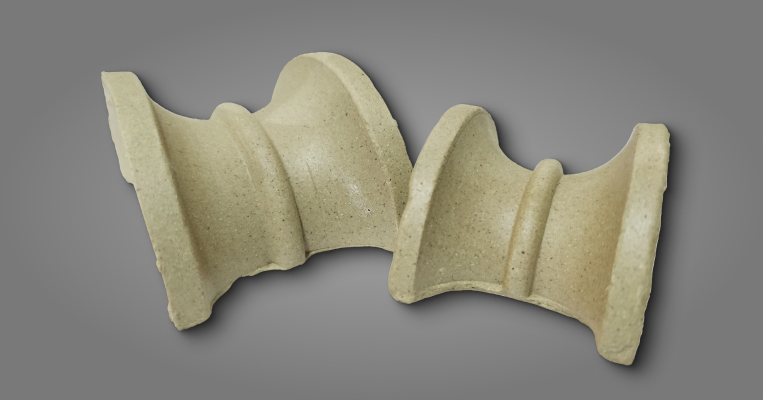

CERAMIC - KUBPAK SADDLE RINGS

Ceramic saddles are one of the most frequently used random packings, especially for corrosive applications. Their smooth surface imparts a high chemical resistance and provides a high degree of stability. Saddles are low-cost packings generally used in acid gas scrubbers, dryer towers, tail gas scrubbers, etc.

These are specifically formulated and fired quality chemical stoneware and porcelain. These are low-cost random tower packing and are completely non ferrous. They are high strength, high capacity, high-efficiency materials and exhibit excellent resistance to all Acids, Alkalis and Solvent operated at high temperature.

Applications:

- Used in scrubbers, drying towers & tail gas scrubbers.

- Impasse towers & absorption towers.

- Cooling tower, scrubber & regeneration tower.

|

|

| Size | 13 to 75 mm |

| Bulk Density | 545 – 725 Kg/m3 |

| Surface Area | 91-625 m2/m3 |

| NTSM | 1.8 to 2.6 |

FAQ'S

The saddle ring is a type of random tower packing suitable for high-capacity and high-performance applications.

It can be beneficial for liquid distribution and improve the flux of the gas.

Compared with pall ring, it has larger flux, less resistance, and higher efficiency. Additionally, it has high rigid and mechanical strength, it is the most widely used type among all the random packing.

Random packing materials were made of ceramic. The use of ceramic has declined because of its brittleness, but it still is used in some applications that require strong corrosion resistance.