Kubpak Pall Rings

METAL - KUBPAK PALL RINGS

|

|

| Size | 10 to 75 mm |

| Bulk Density | 140 – 520 Kg/m3 |

| Surface Area | 120-500 m2/m3 |

| NTSM | 1.8 to 2.2 |

| Thickness | 0.3 to 0.6 mm |

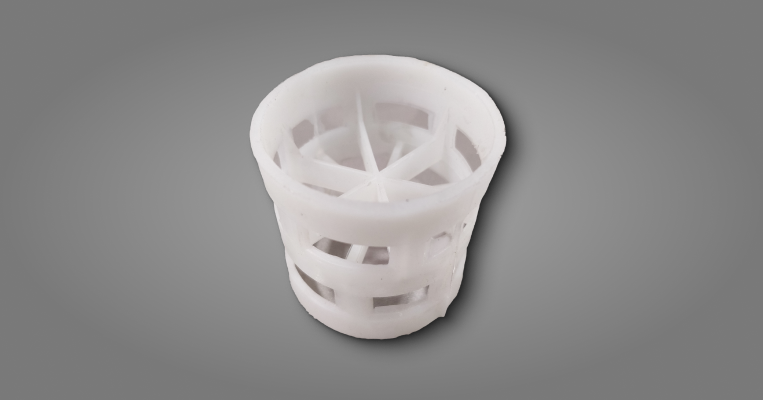

PLASTIC - KUBPAK PALL RINGS

|

|

| Size | 16 to 90 mm |

| Bulk Density | 43 – 95 Kg/m3 |

| Surface Area | 985-340 m2/m3 |

| NTSM | 1.8 to 2.5 |

| MOC | PP, PVDF, PTFE & PFA |

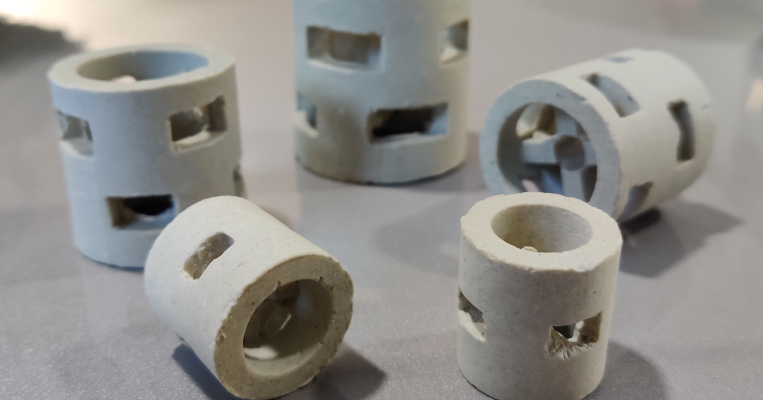

CERAMIC - KUBPAK PALL RINGS

Ceramic Pall ring is a type of classical random packing, which is developed from the Raschig ring. It helps vapor and liquid flow freely through windows, making full use of the inner surface of the ring to improve the distribution of vapor and liquid. It can also improve the separating efficiency. Kuber manufactures pall rings in various details. The ceramic materials utilized while manufacturing are sourced from certified and genuine vendors of the market after sternly looking at their quality and efficiency.

Applications: It is widely used in various packing towers for desiccation, absorption, direct contact cooling, steam stripping applications, etc.

|

|

| Size | 25 to 50 mm |

| Bulk Density | 535 – 640 Kg/m3 |

| Surface Area | 120-220 m2/m3 |

| NTSM | 1.4 to 1.8 |

FAQ'S

Pall ring is one of the most basic, widely used types of tower packing. It is a versatile, affordable option for distillation, absorption, and stripping operations.

Pall ring helps to increase the useful aspects of packing, by giving an increased number of edges to disrupt the flow.

They are available in various types such as Pall ring, Carbon steel pall ring, Metal Pall Ring, etc.

They are the most frequently used form of random packaging are made of metal and plastic.