Why Demister Pads Are a Game-Changer for Industrial Separation?

In this blog, we will explore why demister pads are considered a game-changer for industrial separation systems and how they are revolutionizing various sectors by improving operational efficiency and environmental impact.

In industries that deal with liquid-gas separation, such as chemical processing, oil & gas, and water treatment, demister pads play a crucial role in ensuring the efficiency of the separation process. These specialized pads help remove liquid droplets from gas streams, preventing contamination, reducing maintenance costs, and ensuring cleaner, safer processes.

What Are Demister Pads?

Demister pads are mechanical filters used in separation processes to capture liquid droplets from gas streams. These pads are made from materials like stainless steel or aluminum and are designed to be placed in vessels and pipelines where gas and liquid phases mix. As gas flows through the demister pad, the liquid droplets condense and coalesce, forming larger droplets that can be easily removed from the gas stream.

These coalescing pads are critical for preventing liquid carryover into gas pipelines or for maintaining the quality of gas in applications such as distillation, scrubbing, and absorption. By removing unwanted liquids, demister pads ensure that only cleaner gases are released into the system or the environment.

Key Features of Demister Pads

- Corrosion Resistance:

Demister pads are designed to withstand harsh chemical environments. In industries like chemical processing or oil & gas, where exposure to acidic solutions, saline water, or high-temperature gases is common, these pads are engineered to resist corrosion, ensuring long-lasting durability. - High Efficiency:

One of the main advantages of demister pads is their ability to efficiently capture liquid droplets, even those as small as 10 microns in diameter. This high separation efficiency prevents liquid contamination in the gas stream, ensuring cleaner outputs and improving the overall system performance. - Durability:

Built to withstand demanding environments, demister pads are designed for long-term operation without requiring frequent replacement or maintenance. The mesh structure and material quality of these pads make them robust against physical damage, wear, and corrosion. - Customizability:

Demister pads can be customized based on application needs. Depending on the size of the vessel and the flow rate of the gases, demister pads can be designed with varying mesh densities and thickness to ensure optimal performance. The versatility of demister pads allows them to be used in various industries, including pharmaceuticals, food processing, and oil refineries.

Common Uses of Demister Pads

Demister pads are utilized across a wide array of industries, each with its unique applications:

- In Vessels:

Demister pads in vessels are used to remove liquid droplets from gases in distillation columns, scrubbers, and absorbers. These pads help in cleaning gases by ensuring that liquid carryover does not contaminate downstream equipment or compromise the separation process. - Oil & Gas:

In the oil and gas industry, demister pads are used to ensure that gas pipelines do not carry liquids that could cause corrosion, blockages, or damage equipment. They are often used in separators and dehydration systems. - Chemical Processing:

In chemical processing and petrochemical plants, demister pads are essential for maintaining the purity of gaseous byproducts. They are used to capture and remove liquid phases in a variety of distillation and extraction processes. - Water Treatment Plants:

Demister pads also find application in water treatment facilities, where they are used to improve the quality of gas emissions and reduce moisture in gas streams during aeration and filtration processes.

Why Demister Pads Are a Game-Changer for Industrial Separation?

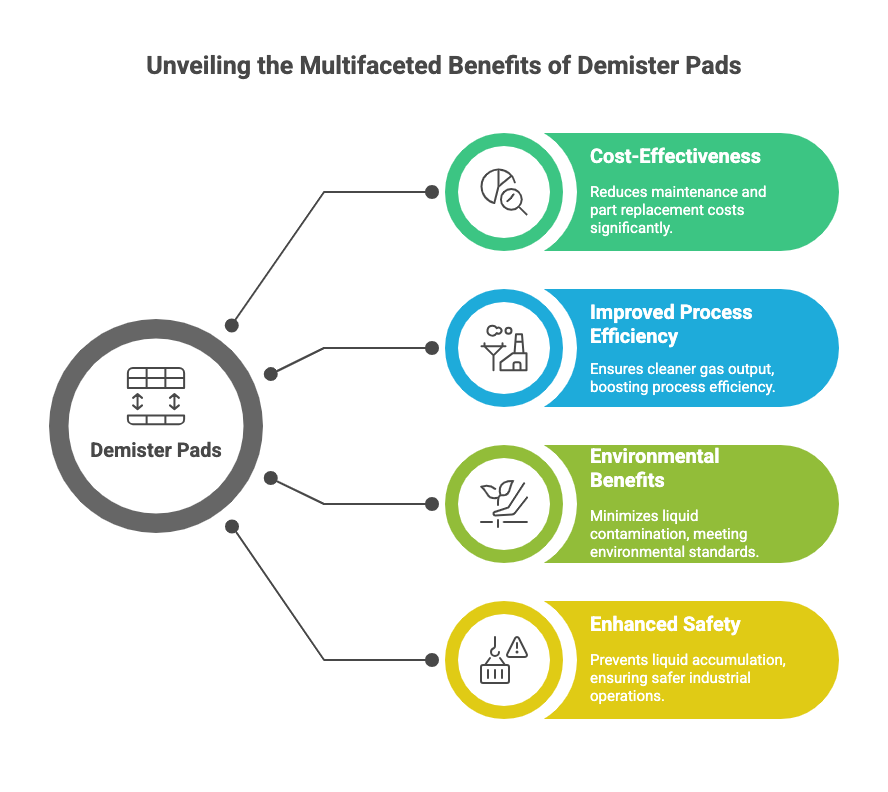

- Cost-Effectiveness:

Demister pads help reduce the need for expensive maintenance and part replacements. By preventing liquid carryover and protecting downstream equipment from contamination, these pads lower the long-term operational costs of industrial systems. - Improved Process Efficiency:

When used in separation systems, demister pads ensure cleaner, drier gas output, resulting in higher process efficiency. The elimination of excess liquids helps improve the overall product quality and yield, especially in industries like chemical processing and oil refining. - Environmental Benefits:

By reducing liquid contamination in gas emissions, demister pads play an important role in meeting environmental standards. They help prevent harmful chemicals and water vapor from entering the environment, making industrial processes more sustainable and eco-friendly. - Enhanced Safety:

In industries dealing with flammable gases or toxic substances, ensuring that liquid phases don’t mix with gases is crucial for maintaining safety. Demister pads are essential for ensuring safe operations by preventing issues such as liquid accumulation in pipelines and tanks that could lead to dangerous conditions.

How to Choose the Right Demister Pad?

- Application-Specific Selection:

The first step in choosing the right demister pad is understanding your specific application. Factors such as gas flow rate, liquid load, and chemical exposure should guide your choice. A mesh-type pad is ideal for removing finer droplets, while coalescing pads are better for larger droplets. - Material Considerations:

Consider the material of the demister pad based on the corrosiveness of the environment. Stainless steel and aluminum are common choices due to their corrosion resistance, but other materials may be more suitable depending on specific needs. - Supplier Selection:

When choosing demister pad suppliers, look for companies that provide high-quality, durable products with customization options. It’s also important to select a supplier that offers warranty, certifications, and after-sales support. - Maintenance Tips:

Regular inspection and cleaning of demister pads are essential for maintaining optimal performance. Ensure the pads are free of any debris or blockages that might impede their efficiency.

Conclusion

Demister pads have become an indispensable component of modern industrial separation systems. By improving separation efficiency, reducing contamination, and providing corrosion resistance, these pads play a key role in industries like oil & gas, chemical processing, and water treatment. Their ability to ensure cleaner gases, reduce costs, and improve safety makes them a game-changer in industrial operations. Investing in high-quality demister pads will not only improve your processes but also contribute to a more sustainable, cost-effective, and efficient operation.

FAQ'S

Demister pads in vessels are used to remove liquid droplets from gases in distillation, scrubbing, and absorbing systems. They help prevent contamination of the gas and ensure cleaner output.

Demister pads work by coalescing tiny droplets of liquid into larger droplets, which can then be separated more efficiently. This ensures that only cleaner gases are passed through the system.

Common materials for demister pads include stainless steel, aluminum, and carbon steel. The choice of material depends on the corrosive nature of the environment and application.

.

The frequency of replacement depends on the operating conditions. Regular maintenance and cleaning will extend their lifespan, but demister pads may need to be replaced when they are no longer efficient at separating liquids from gases.

Yes, demister pads help reduce the pollution caused by contaminated gas emissions. By ensuring cleaner gases are released into the atmosphere, demister pads contribute to a more sustainable industrial process.

Need Help?

We're Here for You!

Got a question or need assistance? Our team is ready to help you every step of the way. Reach out to us, and we’ll get back to you as soon as possible!